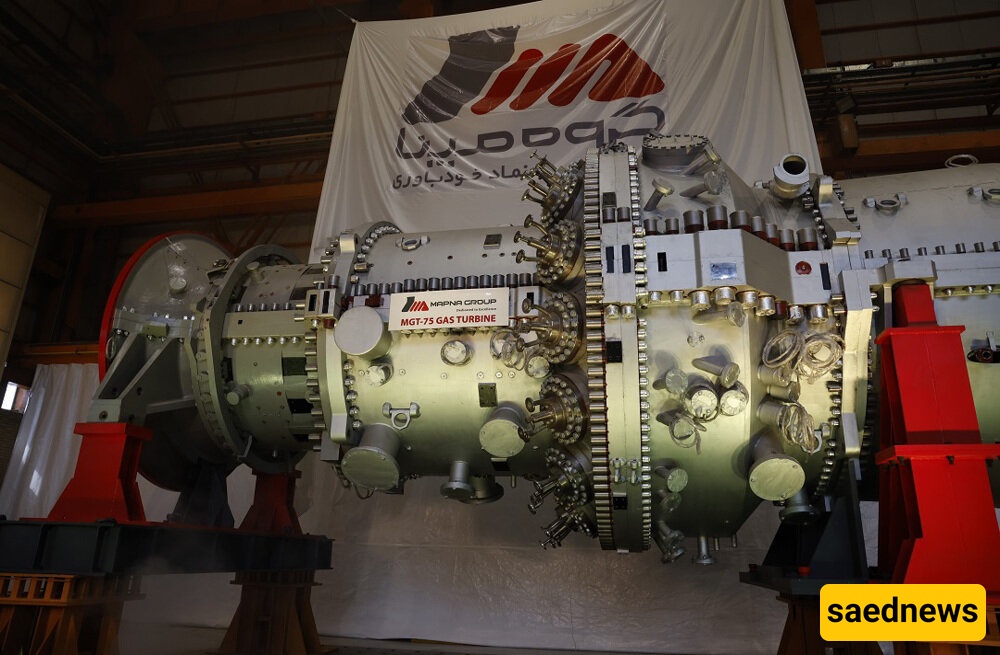

SAEDNEWS: Iran has unveiled its first indigenously developed MGT-75 class-F gas turbine, a technological achievement engineered by MAPNA Group, an Iranian conglomerate working in the areas of power, oil and gas, and railroad projects.

The turbine boasts world-class efficiency, innovative hydrogen-capable combustion, and stands as a testament to Iran’s self-reliant industrial prowess, positioning the country as a major competitor in the global energy arena.

On Monday, Iran's Minister of Energy, Abbas Aliabadi, addressed a gathering of industry leaders and government officials to inaugurate a new era in the nation's energy independence.

With great pride, he introduced the MGT-75 as Iran's first domestically designed and manufactured F-class gas turbine.

Aliabadi praised the turbine as an "engineering masterpiece" and "an honor for Iranian engineers," highlighting that this milestone is the result of efforts put in by young engineers, who have proven their ability to develop technology that meets the highest international standards.

He declared that the implementation of the MGT-75 project marks a major leap forward in the development and modernization of Iran's power plant industry, which would benefit everyone.

He also highlighted its critical timing, noting that as the world undergoes the third and fourth industrial revolutions and enters an age of intelligence, electricity demand is set to surge dramatically.

In this evolving landscape, he asserted, relying on traditional methods would only exacerbate challenges, making it imperative to embrace innovation and modern solutions to build a sustainable future for the next generation.

The minister issued a directive to MAPNA Group, urging it to rise to a global level and actively enter international markets, a goal he described as essential to enhancing the nation's technological stature.

What did MAPNA officials say?

Echoing the minister's visionary statements, Mohammad Owliya, CEO of MAPNA Group, detailed the broader technological ecosystem being developed alongside the landmark turbine.

Adding a layer of technical gravitas, Abbas Fakhr Tabatabaei, product development manager at MAPNA's Turbine Engineering and Manufacturing Company (TUGA), provided a detailed overview of the MGT-75's capabilities.

He positioned the turbine at the technological frontier, classifying its performance at the border between F and the even more advanced H-class.

Fakhr Tabatabaei revealed that this engineering marvel is the product of an immense effort, totaling over 500,000 man-hours of precise engineering work, a testament to the high-level expertise cultivated within MAPNA's subsidiaries, TUGA and Parto.

Homayoun Haeri, Deputy Minister of Electricity and Energy, offered closing remarks, lauding MAPNA's evolution from a producer to an owner of indigenous technology.

He affirmed that the group is now recognized as an important and productive brand in five to six technologically advanced nations and praised its dual role in driving both the economic and strategic objectives of the country's electricity industry, solidifying its place as a foundational pillar of Iran's energy security and technological prowess.

MGT-75 gas turbine

What is an F-class gas turbine?

F-class gas turbines represent a key category of high-efficiency, heavy-duty industrial gas turbines, primarily used for large-scale power generation.

These machines are characterized by advanced engineering, typically delivering 150–250 megawatts in simple-cycle operation with thermal efficiencies ranging from 38 percent to 40 percent.

When integrated into combined-cycle systems, where exhaust heat is used to generate additional steam power, output can exceed 350 megawatts, with overall efficiencies surpassing 58 percent.

The main technological features include:

Sophisticated air-cooling systems for turbine blades.

Advanced combustion chambers designed to reduce nitrogen oxide emissions.

High-temperature alloys and single-crystal components capable of withstanding extreme operational conditions.

F-class turbines also offer fuel flexibility, operating on natural gas, light distillates, or hydrogen blends, supporting modern decarbonization strategies.

First introduced in the 1990s by manufacturers such as General Electric and Siemens, F-class turbines marked a significant advancement over earlier E-class models.

Today, they remain a global benchmark for reliable, high-output power generation across both base-load and flexible grid-support applications.

What gas turbines are used in Iran?

Gas turbines are systematically classified into categories such as E, F, and H, along with newer designations like G, H-A, and H-L introduced by various manufacturers to reflect progressive technological tiers.

These classifications are based on key performance metrics – reliability, operational efficiency, and power output – which are driven by advancements in aerodynamic design, sophisticated cooling systems, high-performance materials, precision manufacturing, digital process controls, and enhanced operational flexibility.

Iran’s total installed power generation capacity reached approximately 92,000 megawatts by 2024, comprising a diverse mix of renewable energy sources, combined-cycle systems, and conventional gas and steam plants.

Within this infrastructure, gas turbines play a dominant role, contributing nearly half of the total capacity and serving as a cornerstone of the national energy supply.

Despite their significant share, most of Iran’s gas turbines rely on outdated E-class or older technologies, which operate at considerably lower efficiency levels compared to modern alternatives.

Currently, advanced-class turbines account for only five percent of the grid’s total nominal capacity. Of Iran’s 50,000 megawatts of gas turbine capacity, just 5,000 megawatts utilize relatively newer F-class technology.

To address this gap, MAPNA Group has been actively pursuing the commercialization and market deployment of its new indigenous F-class turbine.

Doubling the installed capacity of F-class turbines from 5,000 to 10,000 megawatts over the next five years would significantly enhance the country’s energy balance and reduce fuel consumption.

Operating these new units in simple-cycle mode could save nearly one billion cubic meters of natural gas annually. When integrated into combined-cycle configurations, savings could reach nearly four billion cubic meters.

These conservation efforts would yield substantial economic benefits through reduced energy costs, while also delivering meaningful environmental gains by lowering greenhouse gas emissions and mitigating ecological impact.

APNA's MGT-75 gas turbine

What is the MGT-75 gas turbine?

Iran’s energy sector has achieved a landmark breakthrough with the development and unveiling of the MGT-75, the country’s first fully indigenous F-class gas turbine.

This advanced turbine delivers 222 megawatts in simple-cycle operation and up to 330 megawatts in combined-cycle configuration, where it reaches an impressive thermal efficiency exceeding 59 percent.

Engineered to meet domestic energy demands and compete globally, the MGT-75 is tailored to Iran’s unique climatic conditions and diverse fuel resources.

Its ability to operate on natural gas, diesel, and hydrogen blends places it at the forefront of the global transition toward sustainable energy solutions.

The turbine marks a dramatic leap in efficiency, tripling the performance of Iran’s older generation units and significantly reducing carbon emissions. Each one percent gain in efficiency translates to an estimated 2.5 percent reduction in CO₂ output.

Abbas Fakhr Tabatabaei, director of the F-Class Turbine Development Project, emphasized that this achievement reflects the exceptional skill and determination of Iranian engineers in mastering advanced technologies despite external constraints.

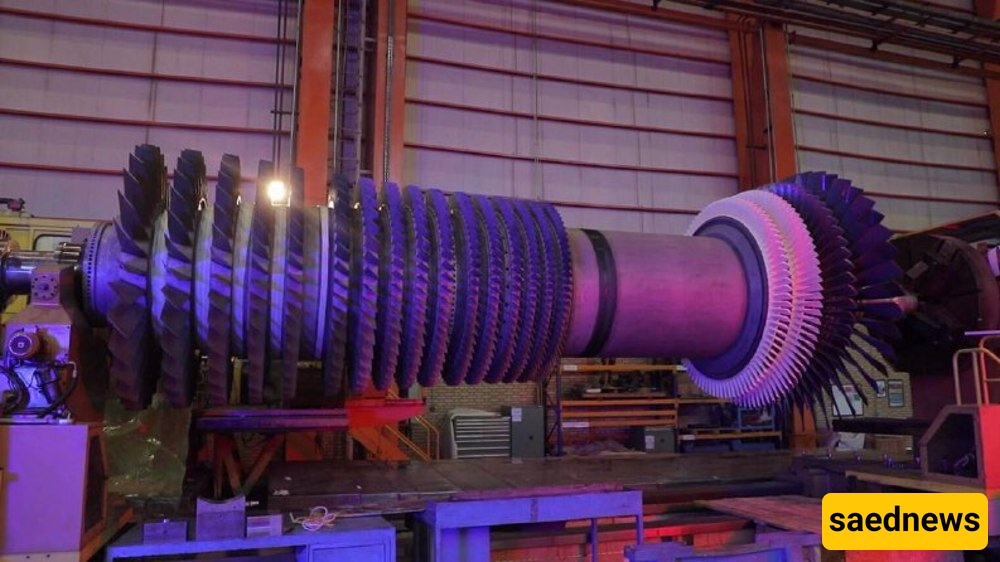

He noted that the MGT-75’s world-class performance is driven by cutting-edge innovations, including a 3D axial compressor, single-crystal and directionally solidified blades, an advanced cooling system, and modern thermal coatings.

The comprehensive upgrade in design and manufacturing was accomplished entirely within Iran, encompassing advancements in software, hardware, and specialized production facilities.

These capabilities now position MAPNA to extend its expertise into other strategic sectors, such as oil field turbine development.

The MGT-75 integrates state-of-the-art features, including sophisticated aerodynamics, advanced materials, and an IoT-based monitoring platform known as "MAPNA Mind," which enables real-time performance tracking and predictive maintenance to ensure reliability and efficiency.

This achievement builds on MAPNA’s successful upgrade of E-class turbines in 2017 and reflects years of intensive research and development by a team of 1,500 engineers, underscoring the company’s strategic commitment to technological independence and innovation.

What is the significance of this turbine?

The full-scale production of advanced F-class gas turbines is concentrated within a select group of seven technologically advanced nations, now including Iran.

The United States, Germany, and Japan have long led the field, represented by industrial giants General Electric, Siemens Energy, and Mitsubishi Power, respectively.

Italy’s Ansaldo Energia also holds a prominent position as an established manufacturer of this high-end technology. In recent years, China has joined this elite group through major state-owned enterprises such as Dongfang Electric. Russia, via Power Machines, has achieved independent production as well, though primarily for domestic use.

With approximately 15 F-class turbines already operational across Iran and more on the way, MAPNA has built a robust local supply chain for strategic components and possesses full in-country capabilities for maintenance, repair, and overhaul.

This self-sufficiency not only strengthens Iran’s energy infrastructure but also opens the door to exporting advanced engineering services and turbine components to regional markets, generating valuable foreign currency and supporting rising energy demands abroad.

Looking ahead, the MGT-75 is set to play a transformative role in modernizing Iran’s power generation fleet. It will enhance grid stability, reduce environmental impact, and advance the country’s broader goals for industrial self-reliance.

MAPNA’s pioneering achievements reflect Iran’s growing strength in high-tech manufacturing and lay the groundwork for continued innovation and leadership in the global energy sector.