SAEDNEWS: Selecting the right technician for your screw compressor is crucial for maintaining and repairing these industrial machines. Due to the complex structure and unique performance characteristics of screw compressors, they require high technical knowledge and expertise to diagnose and fix potential issues correctly.

According to SAEDNEWS,

These problems can be either mechanical or electrical, and solving them requires specialized tools and sufficient experience. Therefore, reviewing the technician's background and capabilities, along with ensuring the quality of services provided and transparency in costs, are key points in this selection. Additionally, when facing serious damage, deciding whether to repair or replace parts becomes particularly important. Choosing an experienced and reputable technician can help reduce costs, save time, and significantly extend the compressor's lifespan.

Technical knowledge and expertise in repairing screw compressors are vital for maintaining these machines' optimal performance. Technicians familiar with the principles and techniques related to these compressors can quickly identify issues. Using diagnostic tools and analyzing warning signs, they can detect faults that might affect the machine's performance. For example, if the compressor makes unusual noises during operation, an experienced technician can promptly identify the cause and take necessary actions to fix the issue.

Understanding the differences between mechanical and electrical issues is critical in screw compressor repairs. Mechanical problems typically involve components like bearings, cooling systems, and shafts, whereas electrical faults may relate to control systems, relays, and switches. Technicians need to be familiar with both types of issues and possess the ability to analyze and resolve faults in both areas. For instance, if the compressor fails to operate due to an electrical system malfunction, the technician should be able to accurately inspect the electrical circuits and related faults to fix the problem.

The technician's experience in repairing screw compressors significantly impacts the quality of services provided. Experienced technicians can quickly diagnose problems and offer appropriate solutions to prevent future failures. Therefore, choosing an experienced technician not only improves the compressor's performance but also reduces unnecessary and frequent repair costs. It is recommended to review the technician's past experience and records before making a selection to ensure high-quality services.

Choosing the right technician for a screw compressor can greatly influence the machine's performance and lifespan. The first step is to review the technician's background and work experience. Experienced technicians are usually familiar with various compressors and can quickly identify and resolve issues. You can use websites and social networks to find others' reviews and experiences or ask friends and acquaintances about reputable technicians.

Quality and transparency of services provided by the technician are also key points in making the right selection. Reputable repair shops should use original and standard spare parts, ensuring high-quality repairs. Ensuring that services come with a warranty is also very important. If a technician does not guarantee their work, the quality of their service may be questionable.

- Use of Original Spare Parts

- Clean and Organized Work Environment

- Post-Repair Support

A clean and organized repair shop environment indicates attention to detail and technical standards. Additionally, technicians who offer post-repair support provide customers with a sense of security, as they can easily contact the technician if further issues arise.

Previous customer reviews and experiences can serve as a reliable source for evaluating the quality of technicians' services. Positive reviews usually indicate customer satisfaction with the services provided and can guide you in making the right choice. On the contrary, negative reviews can be a warning and deter you from choosing that repair shop.

- Review reliable websites and surveys

- Visit social networks and related groups

- Ask friends and acquaintances

Paying attention to others' experiences and conducting research before choosing a technician can help avoid problems and additional costs in the future. By choosing a reputable and experienced technician, you can ensure the optimal performance of your screw compressor.

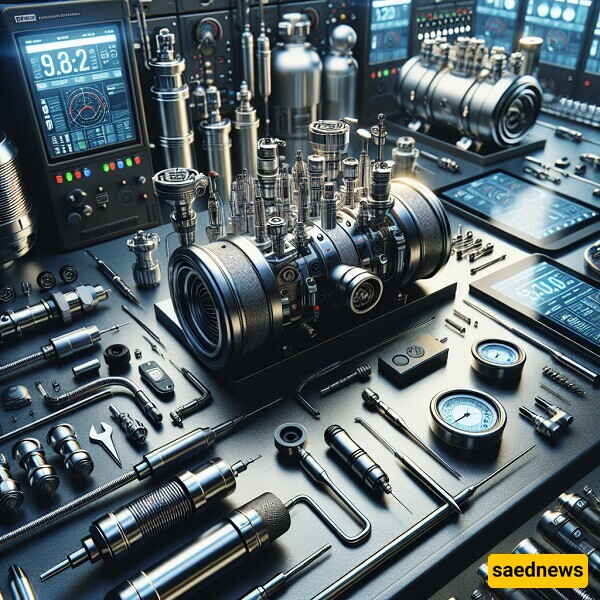

Using specialized tools is essential for repairing screw compressors. These tools include smart sensors, advanced diagnostic equipment, and precise measuring tools. Such tools enable technicians to continuously monitor the compressor’s performance and identify faults before they become serious problems.

Key tools include:

- Temperature and Pressure Sensors: These help technicians identify sudden changes in the compressor's performance.

- Fault Detection Devices: These analyze collected data to find hidden problems.

- Vibration Measuring Tools: Abnormal vibrations can indicate structural issues in the compressor that need inspection.

New technologies, especially in predictive maintenance, have revolutionized repair processes. By using data collected from sensors and machine learning algorithms, it is possible to predict the exact time for maintenance or part replacement.

This approach leads to:

- Reduced Sudden Failures: Predicting problems allows technicians to take necessary actions before failures occur.

- Improved Machine Efficiency: Performing timely maintenance maximizes compressor performance.

- Effective Resource Management: Companies can better manage resources and reduce maintenance costs.

Keeping up with new technologies is essential due to continuous advancements in technology. New technologies not only improve repair quality but also significantly reduce the time and costs associated with repairs. Technicians should continually learn and familiarize themselves with new techniques and tools. Key tips for staying updated include:

- Attending Training Courses: These can help technicians stay up-to-date with the latest technologies and trends.

- Reading Scientific and Technical Resources: Articles and books related to repairs and new technologies can help increase technical knowledge.

- Networking with Other Professionals: Developing networks with other technicians and specialists can lead to sharing experiences and knowledge.

Staying updated is a vital factor for success in repairing screw compressors in today's world.

Cost management in repairs depends on several factors, each having a deep impact on the organization's budget and efficiency. One such factor is the type of equipment. More advanced equipment usually requires specialized and more costly repairs. Additionally, operational conditions like temperature, humidity, and load can affect equipment wear and tear, leading to increased repair costs.